Die casting process in Malaysia is now a crucial part of the country's manufacturing sector which is contributing to major industries such as automotive, electronics aerospace, as well as consumer products. The process of casting metal involves the injection of molten metal into a mold under high pressure in order to produce high-quality, long-lasting and high-quality components. Through the years, Malaysia has developed a well-known reputation for its die casting capabilities, attracting both international and local businesses looking for high-quality manufacturing solutions. Malaysia's central location in Southeast Asia, skilled workforce and rapid technological advances has made it a center in the production of high-quality metal parts. Industries are demanding lighter complicated, high-strength, and complex metal components, the die-casting sector continues to expand to satisfy the ever-changing needs of market. As manufacturing trends shift toward efficiency and sustainability, Malaysia's die-casting industry is poised for even greater expansion in the next few years.

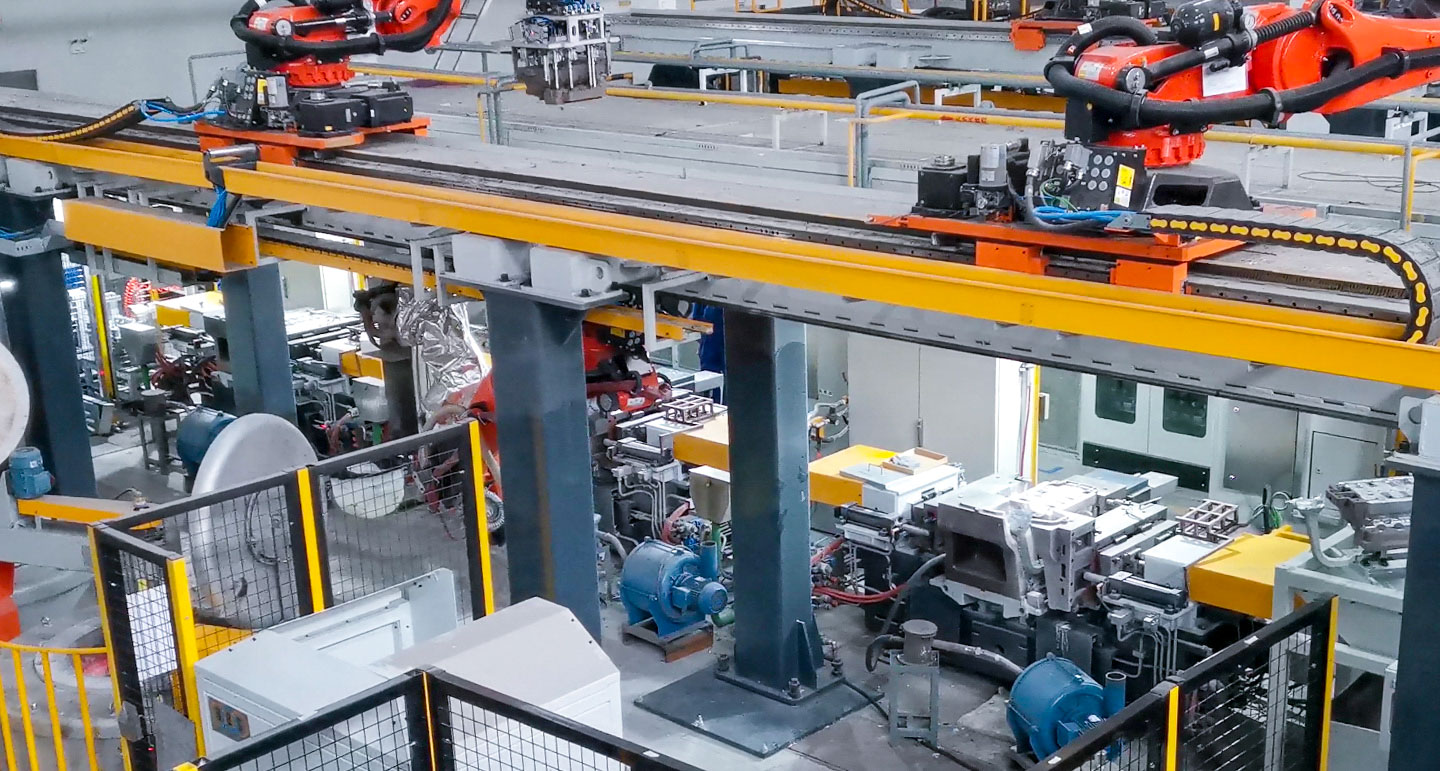

The automotive industry is one of the biggest consumers of die-cast components in Malaysia manufacturing companies rely on this process to produce durable and lightweight vehicle parts. Engine blocks, transmission case structural and transmission cases usually are constructed from magnesium and aluminum alloys due to their high weight-to-weight ratio as well as durability to corrosion. In the transition to electric cars, the need for precision die-cast components has increased as manufacturers focus on enhancing efficiency while reducing overall vehicle weight. Many Malaysian die-casting businesses have made partnerships with global automotive brands providing essential components that meet stringent international standards for quality. The country's role in the automotive industry is further strengthened by the investment into research and development, that help to improve manufacturing techniques and help ensure that companies remain competitive in a rapidly evolving market. Through the integration of automation and smart manufacturing, the die-casting sector is expected to grow more efficient and innovative in the next few years.

Apart from the automotive industry, die casting plays key roles in Malaysia's electronics sector and is among the biggest exporters in the nation. The consistency and precision of components made by die casting make them ideal for manufacturing electronic casings, heat-sinks, and connectors. With the advancement of consumer electronics and telecom devices become more compact and efficient, the need for die-cast components with high precision will continue to increase. Malaysian companies are embracing modern technologies, such as vacuum die casting and semi-solid casting of metal to improve product performance and decrease the chance of imperfections. With a strong supply chain and accessibility to international market opportunities, Malaysian die-casting companies have established themselves as reliable supply chain partners to multinational electronic brands. With 5G technology becoming more prevalent and smart devices are becoming more widespread, the need for high-end die-cast components will likely to grow.

Sustainability has become an important focus for Malaysia's die-casting industry, with companies actively implementing environmentally friendly manufacturing practices. Recycling and reusing metals, specifically zinc and aluminum are now common practice when it comes to die casting, which helps in reducing consumption and saving resources. Numerous manufacturers are also adopting the most energy efficient melting and casting techniques in order to cut down on carbon emissions and the overall consumption of energy. This shift to green manufacturing has led the industry to explore greener casting methods like low-pressure casting and gravity-based die casting, which produce high-quality parts with minimal waste. The coatings and treatments used to increase the durability and resistance of components made by die casting are also being developed with eco-friendly materials. In a world where industries are pushing for greener supply chains, Malaysian die-casting companies are positioning themselves as leaders in the field of sustainable metal casting ensuring long-term competitiveness in the world market. To find added details please head to www.senadiecasting.com.my/

The growth of die casting in Malaysia is also aided by advancements in the design of molds and production and play a crucial component in the creation of top-quality products. Mold-making and precision tooling techniques have evolved to improve the quality of products, their durability and productivity in manufacturing. Through the use of computer-aided design and the use of computer-aided manufacturing software are able to create molds that are extremely complex with tighter tolerances. The advancement in technology allows quicker production times, which reduces expenses and boosting overall efficiency. Utilizing simulation software further enhances mold performance by predicting defects and optimizing casting parameters. As a result, Malaysian die-casting firms can satisfy the increasing requirements of the high-performance industry by ensuring consistency in consistency and quality in their product.

Looking to the future, Malaysia's die-casting industry is predicted to see an impressive growth spurred by the latest innovations, sustainable practices, and growing need for precise metal components. Leaders from the industry and government are working together to enhance research and development initiatives and encourage the use of cutting-edge materials and innovative casting techniques. The workforce training program is designed to equip workers with the necessary skills to operate modern die-casting machinery and automated systems. In a time when industries like electric vehicles, renewable energy and intelligent technology continue to expand, the die-casting industry in Malaysia is well-positioned to meet the growing demand for high-performance metal parts. A strong infrastructure for manufacturing in the country, coupled with its commitment to sustainable development and technological innovation, ensures that Malaysia remains a key actor in the world die-casting industry. By implementing continuous improvement and strategic investments, this sector is expected to continue driving development while maintaining its reputation for high-end precision manufacturing.

Comments on “Die Casting in Malaysia: A Key Player in Precision Manufacturing”